Intelligent Robots

Raytron’s intelligent robots are powered by multi-dimensional sensing technologies and integrated with proprietary end-to-end AI algorithm systems, including multi-sensor fusion SLAM, motion control, human-machine interaction, and image recognition. We have developed wheeled and rail-based inspection robots for both indoor and outdoor use, widely applied in IDC data centers, livestock farming, and more, enhancing inspection efficiency and safety, and reducing operational and maintenance costs.

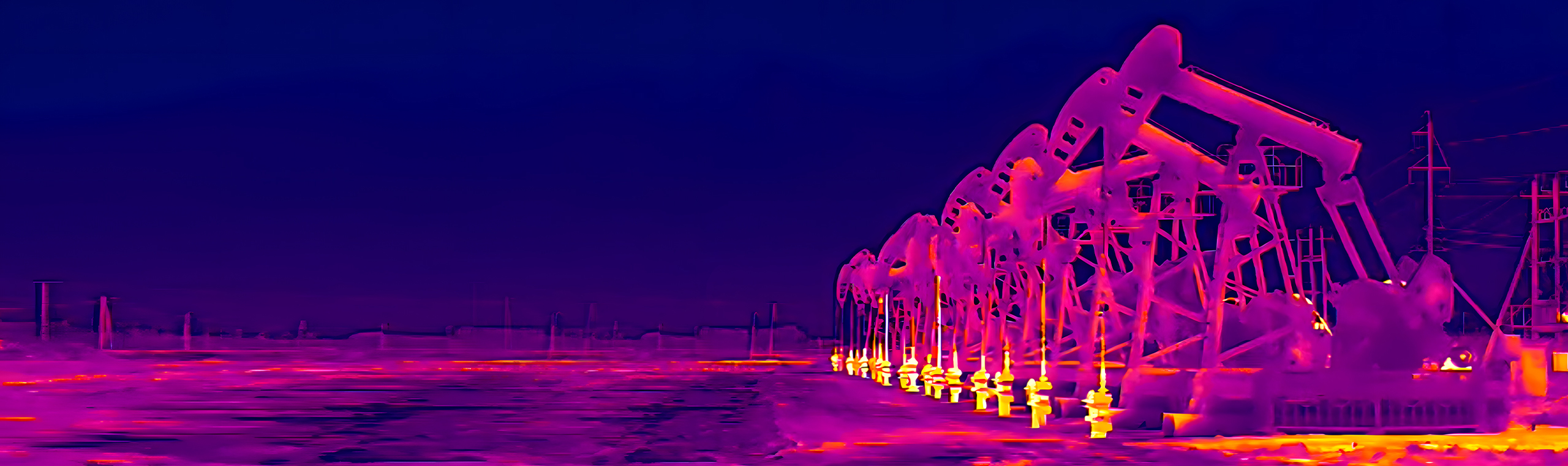

Raytron’s energy-industry inspection robot features an explosion-proof design and multi-sensor coordination, incorporating infrared temperature measurement, intelligent audio-video analysis, and high-precision gas detection capabilities. It is widely used in deployed in hazardous operational environments including oil/gas stations and chemical plants, significantly reducing labor costs while enhancing inspection efficiency.

Raytron’s intelligent livestock inspection robot integrates multi-sensor fusion recognition and autonomous obstacle-avoidance navigation technologies, delivering 24/7 real-time monitoring and reliable operation in extreme conditions, such as high temperature, high humidity, and high corrosion. It provides comprehensive environmental monitoring of farming facilities and incorporates infrared body-temperature monitoring for livestock, alongside audio-video surveillance and recognition capabilities, substantially enhancing farm’s inspection efficiency and management effectiveness.

Raytron’s intelligent inspection robot employs high-precision LiDAR combined with proprietary SLAM technology to achieve highly accurate localization. Equipped with a precision infrared thermal camera, the system achieves temperature measurement accuracy (±2°C). Utilizing its proprietary image preprocessing techniques alongside advanced meter detection and reading-recognition algorithms, the accuracy rate of indicator-light statuses and meter reading recognition can achieve over 96 %. Furthermore, it supports barcode recognition for precise server-asset inventory, with asset-identification accuracy exceeding 99 %.