Carbon Neutrality: Industrial Production Monitoring & Detection in Gas, Power, Oil and Petrochemical Sectors Contribute to Carbon Neutrality

Raytron’s infrared thermal imaging (long/mid/short-wave), laser and AI technologies deliver a comprehensive product portfolio for industrial monitoring, gas-leak detection, and new-energy as well as chemical applications, providing the market and customers with complete, professional industry solutions to accelerate carbon neutrality initiatives.

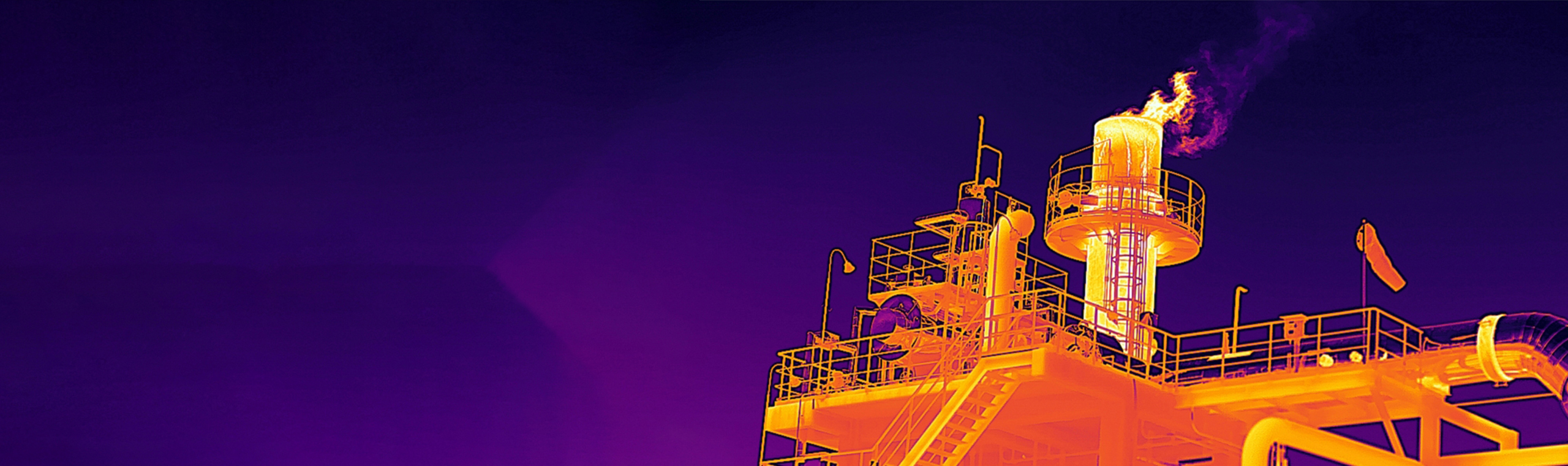

Raytron’s infrared thermal imagers deliver a predictive maintenance solution for the petroleum and petrochemical industries through data acquisition, analysis, and management, accurately assessing equipment operational health, enabling intelligent fault detection, automated diagnosis, and fault-cause reporting. By making equipment status fully controllable, it helps oil and petrochemical operators boost efficiency and safeguard safety.

Raytron’s gas‑detection infrared thermal cameras deliver rapid scanning with second-level response in challenging environments, utilizing high‑resolution thermal imaging to accurately pinpoint leak locations. The cooled gas‑detection thermal imager, engineered to suppress environmental interference, detects ppm‑level micro‑leaks of methane and SF₆ with high sensitivity. With its capabilities for non‑contact, wide‑area monitoring, it is widely deployed in petrochemical, gas, and environmental monitoring applications, providing an intelligent solution for industrial safety and environmental protection.

Lithium‑ion batteries are prone to thermal runaway during storage when subjected to impacts or compression, potentially causing fires or explosions. By employing infrared thermal imaging for full‑scene coverage, the system continuously monitors for temperature anomalies and smoke‑or‑flame hazards, issuing real‑time alerts in conjunction with audible‑visual alarm devices and a remote monitoring interface to ensure safe operations.