The petrochemical industry operates under conditions that are inherently demanding and fraught with risk. High temperatures, pressures, and the omnipresent threat of corrosion and oxidation require vigilance and innovation to ensure safety and operational efficiency. In this high-stakes environment, thermal imaging cameras have emerged as a pivotal asset, offering unparalleled insights and predictive maintenance capabilities. This article delves into the top uses of thermal cameras in the petrochemical sector and how they are transforming safety and productivity.

Infrared Thermal Imaging Technology in the Petrochemical Industry

The challenges faced by the petrochemical industry are substantial. Equipment operates continuously under high temperatures, pressures, and in the presence of corrosive and oxidizing agents. A single malfunction can lead to significant losses. To preemptively identify issues, ensure safe production operations, and extend the service life of equipment, thermal imaging cameras have become indispensable.

Infrared thermal imaging technology operates on the principle of infrared radiation temperature measurement. It utilizes infrared imagers to swiftly and conveniently capture the thermal signature of the object under scrutiny. By discerning temperature variances across different parts of the equipment—even within the same component at various intervals—this technology can diagnose operational anomalies and provide a foundation for equipment status monitoring reports and effective maintenance strategies.

Thermal Imaging Camera Detection in Petrochemical Applications

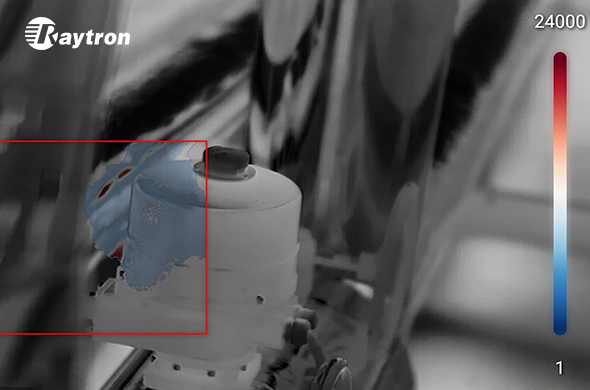

Petrochemical enterprises rely on pipelines for the transmission of vapors, raw materials, and products, often insulated to maintain process conditions. However, these insulation layers can conceal critical issues until it's too late. Thermal imaging cameras are adept at detecting insulation damage and leaks, offering a proactive approach to maintenance and safety.

Coke Blockages: Thermal cameras can identify blockages caused by coke buildup, which can disrupt the flow and efficiency of pipelines.

Wear and Corrosion: Thin or compromised sections of pipes are prone to wear and corrosion. Thermal imaging can pinpoint these areas before they escalate into significant issues.

Pipe Cracks and Leakages: Detecting cracks and leaks in pipelines is crucial to prevent environmental contamination and safety incidents. Thermal cameras provide a non-invasive means to identify these risks.

Insulation Layer Integrity: The condition of insulation layers is vital for maintaining operational temperatures and preventing heat loss. Thermal imaging can quickly assess the integrity of these layers.

Advantages of Thermal Imaging Cameras

The advantages of thermal imaging cameras extend beyond enhanced monitoring accuracy. They reduce reliance on manual inspections, lowering costs and increasing safety by automating the detection of potential hazards.

Identifying and Diagnosing Issues with Thermal Cameras

Thermal cameras are not just about detecting problems; they are also essential tools for diagnosing the root causes of these issues. For instance, a hotspot in a pipeline might be due to a coke blockage, or it could be a sign of internal corrosion. By analyzing the thermal data, maintenance teams can devise targeted solutions that address the specific problem, rather than resorting to more costly and time-consuming blanket repairs.

Enhancing Safety with Real-Time Monitoring

Real-time monitoring is another critical application of thermal cameras in the petrochemical industry. By continuously monitoring equipment, any anomalies can be detected and addressed immediately, often before they become critical. This real-time insight is invaluable for maintaining a safe working environment and preventing accidents.

Cost-Effective Solutions for High-Stakes Industries

The petrochemical industry operates with high stakes, where the cost of downtime or an accident can be astronomical. Thermal cameras offer a cost-effective solution by enabling predictive maintenance and early issue detection. By avoiding major failures and reducing maintenance costs, these cameras provide a significant return on investment.

The application of thermal imaging cameras in the petrochemical industry underscores their critical role in bolstering production safety and efficiency. As technology advances, we can anticipate an even greater impact of thermal imaging in the future, with more sophisticated cameras providing deeper insights and predictive analytics.