Raytron Leads the Way to Carbon Neutrality with Advanced Infrared Thermal Imaging Technology

In our increasingly environmentally conscious world, achieving carbon neutrality has become a paramount goal for industries and individuals alike. With climate change driven largely by rising CO₂ emissions, innovative solutions are in high demand. Among these, infrared thermal imaging stands out—a powerful technology that makes the invisible visible, helping to reduce costs, improve safety, and accelerate the transition to a low-carbon future.

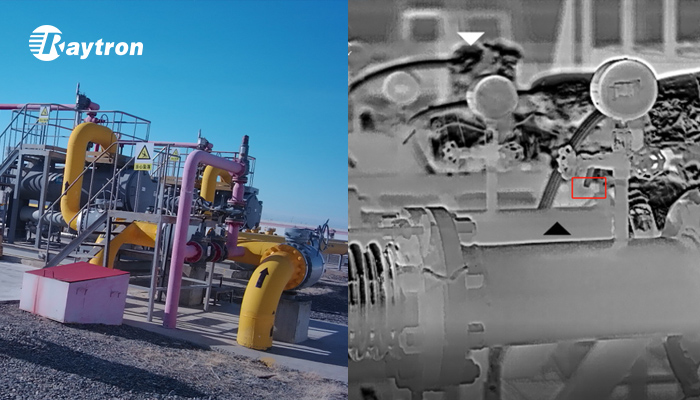

1.Infrared Thermal Imaging Revolutionizes Gas Detection

Many industrial processes involve gases invisible to the human eye, but their leaks emit thermal radiation detectable by infrared cameras. Gas-detection thermal imagers enable rapid scanning of large areas, such as pipelines, storage tanks, and industrial facilities, making it easier to locate leaks quickly and accurately. Benefits include:

lReducing emissions of potent greenhouse gases like CO₂ and methane.

lImproving safety and preventing potential explosions or other accidents.

Regular inspections with thermal imaging enhance safety and environmental performance, ensure compliance with regulations, and minimize the environmental impact of industrial operations.

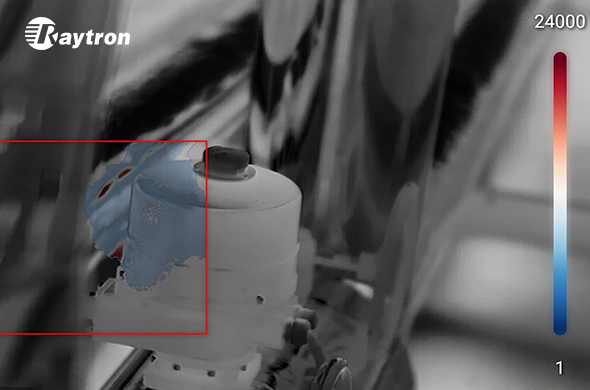

2.Thermal Cameras for Preventive Maintenance Boosts Safety and Sustainability

By detecting subtle changes in thermal radiation, infrared cameras identify potential problems before they escalate. Overheating in electrical systems, mechanical components, and industrial machinery appears clearly as thermal anomalies on camera. For instance, a faulty connection often emits excess heat, which is immediately visible on a thermal map. Raytron’s advanced infrared thermal cameras, with NETD as low as 30mK and a 12μm detector, deliver high-resolution thermal imagery to pinpoint hotspots and hidden faults. Early detection facilitates timely repairs, prevents costly unplanned downtime, and extends equipment service life. This not only cuts expenses but also reduces waste and resource consumption, supporting more sustainable operations.

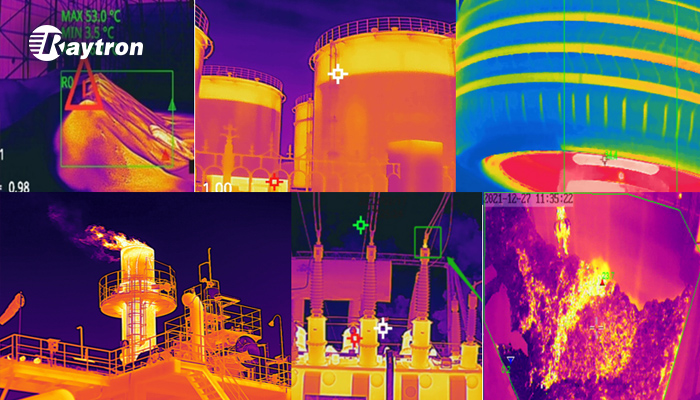

3.Thermal Imaging Empowers Non-Contact Industrial Temperature Measurement

In settings, such as boilers, rotary kilns, or molten steel furnaces, conventional sensors fail and manual inspection is impossible. Raytron’s high-temperature thermal cameras enable non-contact temperature measurement up to 1,000°C, automatically identifying early signs of lining degradation, such as thinning, cracks, bulges, and delamination. By alerting operators before failures escalate, Raytron’s thermal imaging solutions help avoid catastrophic failures, thereby enhancing personnel safety and reducing emissions spikes.

4.Infrared Thermal Imaging for Building Inspection Enhances Energy Efficiency

According to global climate data, buildings are the world’s second-largest source of emissions, with 10.9% from residential and 6.6% from commercial sectors. Preventing energy leakage is therefore essential to decarbonization efforts. Raytron’s infrared cameras for building diagnostics can scan large building surfaces in seconds, revealing insulation gaps, rooftop failures, and air leaks in windows or doors. They also detect heat loss from damaged pipes, steam leaks, and inefficient HVAC systems. By addressing these defects, building owners can dramatically cut energy consumption, reduce carbon emissions, and improve overall building performance.

Raytron’s Vision for a Net-Zero Future

As a leading global provider of infrared solutions, Raytron supports diverse industries, from power grid monitoring and industrial automation to photovoltaic maintenance and building diagnostics. By revealing hidden energy losses and enabling predictive maintenance, Raytron empowers organizations to operate more efficiently and with greater environmental responsibility. Through continuous innovation, Raytron is positioning thermal imaging as a foundational technology in the global pursuit of carbon neutrality.