Raytron's Thermal Cameras Enhance Industrial Safety Through Real-Time Infrared Monitoring

As summer temperatures soar at industrial sites, risks multiply. Electrical overloads, equipment overheating, and spontaneous combustion of hazardous waste become more common. Traditional manual inspections cannot deliver continuous risk monitoring. Raytron’s infrared thermal imaging technology solves this problem with real-time temperature measurement, non-contact scanning, and 24/7 intelligent surveillance. By delivering accurate, reliable thermal data, Raytron’s thermal solutions empower technicians to prevent fires, explosions, and catastrophic failures, fortifying industrial safety at the source.

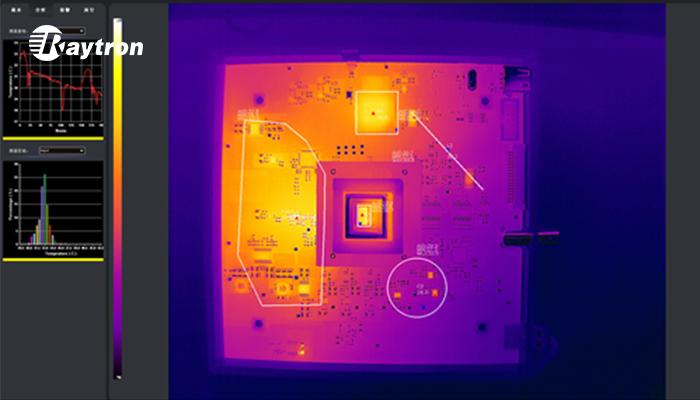

Thermal Cameras for Electrical Inspection:

Prevent Failures Before Ignition

For technicians, manual point-by-point checks are time-consuming and prone to oversights. The Raytron RT630 Expert Thermal Camera revolutionizes power grid inspection with the following advantages:

l640×512 high-resolution thermal detector scans wide areas in minutes—not hours.

l35mK NETD sensitivity (0.035°C) pinpoints subtle temperature anomalies invisible to the naked eye.

lSmart image stabilization generates sharper, clearer thermal maps for actionable insights.

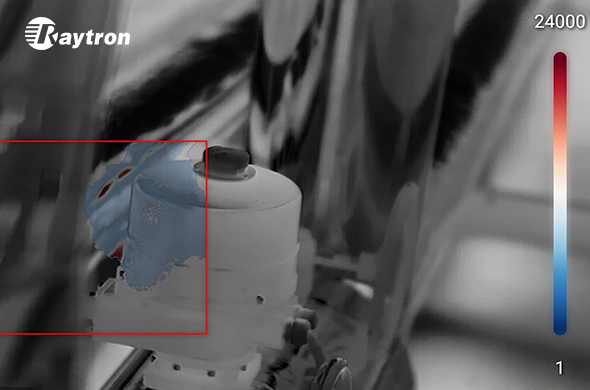

Thermal Monitoring for Battery Energy Storage Systems:

Prevent Thermal Runaway to Enhance Safety

Lithium batteries in EVs and energy storage systems pose hidden thermal runaway risks. Leading automakers and energy providers deploy Raytron’s TN220 Thermographic Cube Camera across warehouses and assembly lines. The TN220 features a 256×192 WLP infrared module which visualizes surface temperature distribution across battery packs. Its compact and PoE-powered design allows flexible deployment in tight spaces, providing continuous, visualized temperature oversight to keep production and storage safe.

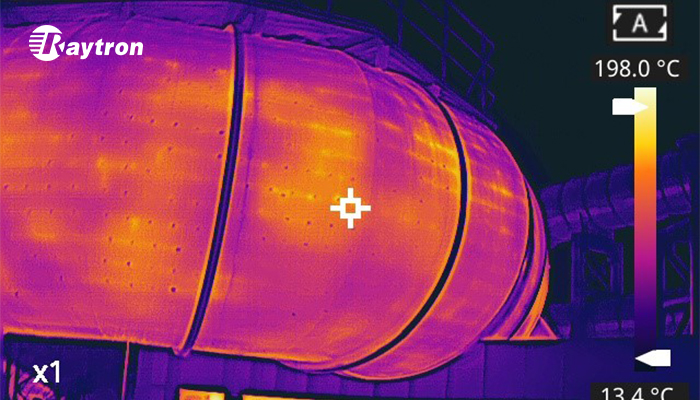

Infrared Remote Imaging of Hazardous Waste:

Enable Inspections in Ultra-high Temperature Environments

In hazardous environments where temperatures are extremely high, direct access is impossible and contact sensors may be damaged. Raytron’s TN460U online ultra-high temperature camera, however, thrives in conditions from 0℃ to 2000℃. Equipped with an uncooled 640 × 512 infrared FPA detector, it generates detailed thermal maps even in smoke. Whether inspecting furnace walls for cracks, scanning slag beds for cold spots, or diagnosing refractory failures, technicians rely on this non-contact temperature measurement tool to pinpoint failures, preventing unexpected shutdowns and mitigating environmental risks.

What Makes Raytron a Top Thermal Camera Manufacturer?

Raytron is a global leader in uncooled thermal imaging cameras, with nearly half of its workforce dedicated to R&D and over 2,100 patents filed. Committed to driving innovation in industrial safety, firefighting, environmental protection and ADAS, Raytron continues to deliver advanced solutions that propel the sector toward a smarter, safer future.