Infrared thermal imaging technology is becoming a vital tool in building inspection, enhancing both on-site safety and operational efficiency. By capturing subtle temperature variations across building surfaces, this technology enables professionals to uncover underlying issues—such as hidden moisture, insulation failures, or electrical anomalies—that are often invisible to the human eye. This innovative approach is transforming how building safety assessments are conducted

How Can Thermal Imaging Improve Building Energy Efficiency And Safety?

Buildings face increasingly complex environmental and structural demands. Thermal imaging technology has redefined the way buildings are inspected. It provides fast, accurate, and actionable data that helps professionals efficiently assess building conditions by monitoring air leaks, insulation, water intrusion, and identifying high-temperature electrical hazards. By integrating infrared thermal imaging into regular inspections, stakeholders can enhance building safety while complying with global building and energy performance standards.

1.Infrared Thermal Imaging For Air Leak Detection

Air leaks can significantly reduce a building’s energy efficiency and living comfort. Through thermal imaging for building inspection, building inspectors can efficiently detect air leak around window frames, door seals, and ventilation systems, areas that are commonly missed in traditional inspections. By using infrared thermal imaging technology, home inspectors can accurately identify leak locations and provide targeted recommendations for stopping them. This not only reduces heat loss and lowers energy bills but also improves the building’s overall thermal performance.

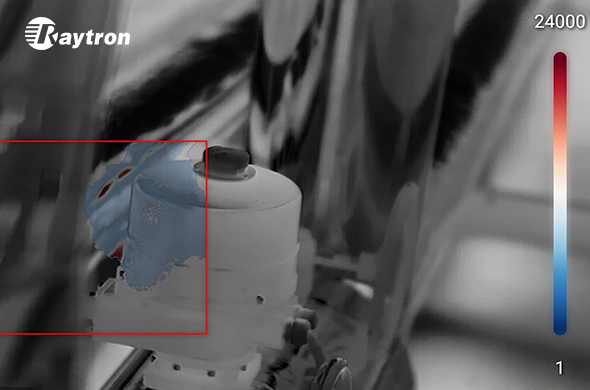

2.Using Infrared Technology To Detect Foam Boad Problems

New and old buildings are prone to common problems such as damaged or poorly installed exterior wall insulation layer. With Raytron’s thermal imaging, inspection technicians can efficiently identify these poor insulation defects, enabling buildings to regulate internal temperatures more effectively and reduce the load on air conditioning systems.

3. Infrared Thermal Camera for Water Leak Inspection

Water leaks are a key factor contributing to mold growth, structural damage, and even potential harm to human health. Raytron’s thermal imaging cameras are highly effective for detecting hidden leaks in walls, floors, and ceilings, which are often missed by traditional inspections. Unlike traditional methods, infrared thermal imaging enables non-invasive, non-destructive inspections, allowing professionals to detect water leaks across large areas in real time, from the surface to deeper layers, without damaging the structure.

4. Using Thermal Imaging To Detect Electrical System Overheating Hazards

Overheating of electrical systems is one of the leading causes of building fires. Thermal imaging enables early detection of high-temperature hazards in circuit boards, distribution boxes, and transformers. Taking preventive measures before problems escalate can help improving safety, reducing downtime, and extending system life.

5. Using Infrared Thermal Imaging To Support Energy-Efficient Building Renovation

Before renovating a building, thermal imaging inspections can provide essential data on heat loss, insulation conditions, and electrical loads. This information is critical for architects and engineers to develop more energy-efficient renovation plans, helping them plan scientifically based on the actual conditions of each building.

Raytron’s infrared thermal imaging technology is reshaping the building inspection industry by offering efficiency, non-invasive, and highly accurate diagnostics. From detecting air and water leaks to identifying overheating hazards, thermal imaging supports safer infrastructure and smarter renovation planning. As energy efficiency and safety standards become increasingly important worldwide, integrating Raytron’s thermal imaging solutions into regular inspection routines is not only practical—but essential for sustainable building management.