Gas station safety is crucial to prevent environmental and financial damage. One of the most effective tools for early leak detection is thermal imaging technology. Thermal cameras have proven to be invaluable in identifying leaks quickly, allowing for prompt intervention before they escalate. This blog explores how thermal cameras detect leaks at gas stations and why they are a preferred method for leak detection.

Why Gas Leaks at Stations Are a Major Concern

Gas stations handle flammable and volatile substances, making them particularly vulnerable to leaks. Undetected leaks can lead to dangerous consequences, including environmental pollution, fire hazards, and costly repairs. Even a small leak can seep into the soil, groundwater, or atmosphere, posing risks to public health and safety. This is why early leak detection is critical at gas stations.

How Do Thermal Cameras Work for Leak Detection?

Thermal cameras operate by detecting infrared radiation, which is invisible to the naked eye. They create thermal images that show temperature variations on surfaces, making it easier to identify anomalies. When a gas leak occurs, it usually results in temperature changes due to the escaping gas, which is often cooler or warmer than the surrounding environment.

By highlighting these temperature differences, thermal cameras can visualize gas leaks as "hot" or "cold" spots. This rapid visual detection allows for quick identification, even in hard-to-reach areas like underground pipes or complex piping systems.

Advantages of Thermal Cameras for Gas Station Leak Detection

Non-Invasive Monitoring

Thermal cameras allow operators to detect leaks without physical contact. This non-invasive approach is crucial for gas stations, where direct access to fuel tanks and underground pipes can be challenging and disruptive.

Early Detection

Thermal cameras can detect leaks early, before they become visible to the naked eye. This early detection minimizes the risk of accidents, contamination, and costly repairs. The ability to visualize leaks in real-time helps maintenance teams take immediate action.

Accuracy in Identifying Leak Sources

Thermal imaging technology can pinpoint the exact location of a leak, reducing the guesswork involved in leak detection. This accuracy ensures targeted maintenance and repairs, saving time and resources.

Efficiency in Routine Inspections

Thermal cameras make routine inspections faster and more efficient. They can quickly scan large areas, identify potential issues, and prevent future problems. This efficiency is particularly beneficial in high-traffic environments like gas stations, where downtime must be minimized.

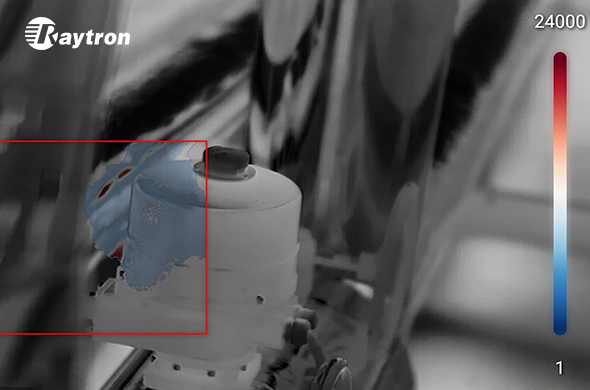

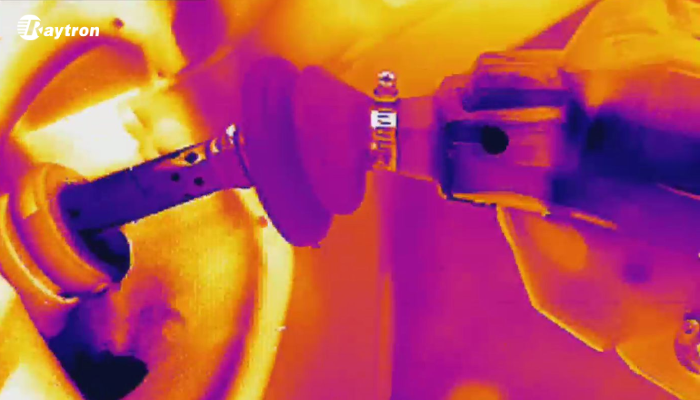

Raytron’s handheld gas infrared imager can directly observe leaking gas under the vehicle.

Common Applications at Gas Stations

Thermal cameras are used in several key areas of gas stations to monitor for leaks, including:

· Fuel Tanks: Detecting leaks in underground or above-ground tanks.

· Pipelines: Identifying leaks in pipes that transport fuel from storage to the pumps.

· Dispenser Nozzles: Checking for minor leaks at fuel nozzles, which may otherwise go unnoticed.

·Valves and Seals: Ensuring that critical components like valves are functioning correctly without leaks.

Key Features to Look for in Raytron's Thermal Camera for Gas Stations

High Sensitivity

Raytron's thermal camera with high sensitivity can detect even the slightest temperature variations. This sensitivity is essential for catching small leaks that could grow over time.

User-Friendly Interface

A simple and intuitive interface ensures that gas station staff can operate the device effectively, even without specialized training. Clear thermal images make identifying leaks easier and faster.

Durability and Weather Resistance

Gas station environments can be challenging, with exposure to weather and harsh conditions. Raytron‘s durable thermal camera that withstands these conditions is essential for reliable performance.

Data Storage and Analysis

Many modern thermal cameras offer data recording features, such as Raytron's product, allowing users to track and analyze leak patterns over time. This data can inform maintenance schedules and help identify recurring issues.

Raytron’s handheld gas infrared imager helps operators quickly determine whether there is a leak.

Thermal cameras are a powerful tool for detecting leaks at gas stations. They provide a fast, accurate, and non-invasive way to identify leaks before they become serious threats. Investing in thermal imaging technology helps gas stations maintain safety, protect the environment, and reduce repair costs. It’s a proactive solution that enhances gas station maintenance and ensures regulatory compliance.