2026 Guide: How AI Thermal Cameras Are Transforming Industrial Gas Leak Detection

AI thermal cameras for industrial gas leak detection address this challenge by combining infrared thermal imaging with AI-based analysis to visualize invisible gas plumes and support faster, more reliable inspections. By transforming subtle thermal patterns into clear, actionable visuals, these systems help industrial teams detect leaks that might otherwise go unnoticed.

The Hidden Risks of Industrial Gas Leak Detection

For industrial safety teams, routine gas leak inspections are often a frustrating, high-stakes chore. Manual sniffers require back-breaking crouching to get within inches of potential leak points, missing tiny seepages that slip through cracks. Fixed sensors bombarded you with false alerts from wind gusts, humidity spikes, or nearby machinery heat, wasting precious time sifting through noise. To make matters worse, fog, darkness, or dust render basic tools useless, leaving blind spots in critical areas. Micro-leaks lurk unseen in pipe joints or valve crevices, quietly escalating into explosions, toxic exposure, or costly downtime. What should be a proactive safety measure becomes a game of chance—one that puts safety team, operations, and bottom line at constant risk.

How AI Thermal Camera Detection Works

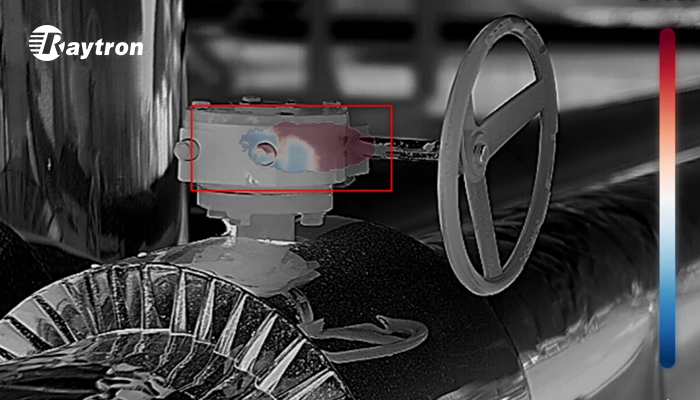

AI thermal camera leverages the basic principle of thermal imaging: all objects emit infrared radiation (heat), and leaking gases interact with this radiation differently than surrounding air. This creates subtle thermal contrasts that standard cameras can’t see, but infrared thermal camera sensors can capture and convert into visual images. What sets AI-enhanced handheld thermal cameras apart is their ability to make sense of these images. Unlike basic thermal imaging technology that only shows temperature differences, AI-powered gas detection cameras use specialized algorithms to isolate gas plumes from cluttered backgrounds like pipes, machinery, or weather elements. The AI automatically outlines leak boundaries, uses color coding to show plume spread, and highlights potential leak sources. It also filters out false signals (such as wind drafts or temperature variations) that often trigger unnecessary alerts with traditional tools. The result is clarity: even tiny leaks that would slip past manual checks become visible. Operators don’t need advanced training to interpret the images—color-coded visuals and simple alerts make it easy to identify, locate, and assess leaks quickly.

Real-World Uses of AI Thermal Camera for Industrial Gas Leak Detection

Raytron is changing the industrial gas leaks visible with its self-developed Ray GasSniffer Algorithm, integrated seamlessly into the handheld infrared thermal camera. This AI-powered innovation transforms how industrial teams detect leaks, turning undetectable seepages into clear, actionable visuals. The algorithm’s core strength lies in precision. Thermal imaging for gas leaks automatically captures and segments gas leak areas, rendering plume contours and diffusion paths easy to trace, even for untrained operators. Beyond visualization, AI-Powered Thermal Imaging Dual-spectrum integrated in robots adds critical safety intelligence: concentration inversion technology enables accurate risk assessment, while real-time intelligent alarms ensure no micro-leak goes unnoticed. Whether deployed in petrochemical operations, power-line inspections, or environmental monitoring, this AI thermal imaging solution empowers teams to address hazards proactively, strengthening industrial safety with smart, reliable infrared tech.

About Raytron

As a leader in infrared thermal imaging, Raytron drives industrial safety through innovations like the Ray GasSniffer Algorithm. Rooted in the belief of “creating incremental value for customers with technological advancement”, Raytron is continually delivering reliable thermal imaging tools to safeguard industrial operations, environments, and teams globally.