Fire Safety Goes Proactive: How Thermal Imaging Shift Fire Safety from Reaction to Prevention

According to U.S. Fire Administration in 2024, fires cause over $20 billion in property damage annually in the U.S. alone, U.S. home fires most often start in specific functional areas such as kitchens, living rooms, and bedrooms, while fires originating in structural areas such as attics or ceiling spaces—areas that may be less easily noticed—also contribute to property loss. In recent years, thermal imaging have emerged as a impactful technology for fire hazard prevention , shifting fire safety from reactive response to proactive prevention.

Why early-stage fire risks are often “invisible”

“Invisible before occurrence” accurately describes the nature of most hidden fire risks. Unlike open flames or thick smoke, the early stages of fire development, such as overheating electrical components, smoldering insulation, or friction-induced hotspots, produce no visible signs to the naked eye. Traditional detection systems, such as smoke detectors or heat detectors, are designed to trigger alerts only after smoke or excessive heat has already formed. This delay is often the reason why small, manageable hazards evolve into full-scale fires.

How Thermal Imaging Detect Hidden Fire Risks

Thermal imaging technology, integrated into firefighting cameras and fireman cameras, addresses the invisibility gap by detecting thermal energy (heat) rather than visible light. All objects above absolute zero emit thermal radiation, and when an object’s temperature rises above its surrounding environment—indicating a potential fire hazard—it appears as a distinct hotspot in thermal images. This capability allows firefighters and safety professionals to identify hidden risks long before smoke or flames are present.

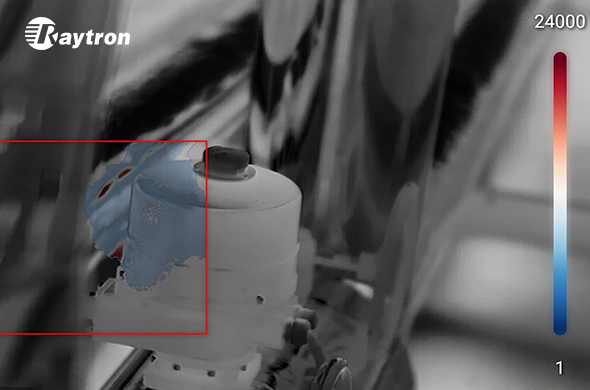

According to the fire safety industry research from National Fire Protection Association, thermal imaging technology can detect tempperature anomalies before smoke is visible, handheld thermal imaging camera are particularly effective in hotspot detection due to their portability and precision, making them ideal for on-site fire safety inspections. These devices convert thermal radiation into visible images, with different colors representing varying temperature levels—typically red, orange, and yellow for high temperatures (hotspots) and blue or purple for cooler areas. During inspections, safety teams can use these handheld thermal imaging camera for firefighting to scan electrical panels, machinery, structural components, and confined spaces, quickly identifying abnormal heat patterns that signify potential hazards.

For example, a loose electrical connection that is overheating will appear as a bright hotspot in a thermal image, even if it is hidden behind a wall or inside a piece of equipment. In addition to hotspot detection, thermal imaging enhances other critical fire safety functions. Long-range detection capabilities allow firefighters to identify fire location from a safe distance, even in low-visibility conditions caused by smoke or darkness. Smoke detection is also improved, as thermal imaging can penetrate smoke to reveal the source of the fire, enabling more targeted and effective response. Unlike traditional cameras, which rely on visible light, thermal imaging operates independently of lighting conditions, making it a reliable tool for both daytime inspections and nighttime emergencies.

How to Use Handheld Thermal Imaging Cameras Proactively

The value of thermal imaging extends beyond simply detecting hotspots. Thermal camera enables a proactive fire prevention process that transforms how fire safety is managed. When a handheld thermal imaging camera identifies a hotspot, the next step is to assess the risk: determining the cause of the overheating, evaluating the potential for ignition, and implementing immediate corrective actions. This process turns a potential disaster into a manageable issue, significantly reducing the risk of fire.

During a routine inspection of a high-rise commercial building’s electrical riser room, a thermal imaging camera detects a hotspot in an electrical panel. In industrial settings, thermal imaging inspections of machinery can identify worn bearings or misaligned components that generate excessive heat, allowing for maintenance before a fire breaks out. This proactive approach not only prevents fires but also reduces downtime, maintenance costs, and potential liability. Fire safety professionals recommend integrating handheld thermal imaging cameras into 24/7 routine inspections to address hidden risks that traditional methods miss, in compliance with NFPA 72 (National Fire Alarm and Signaling Code).

Why Real-Time Monitoring with Thermal Cameras Cuts Fire Losses

Real-time monitoring is a critical component of modern fire safety, where Raytron’s thermal imaging technology plays a key role in enabling this capability. Unlike scheduled inspections, real-time monitoring provides continuous surveillance of high-risk areas, ensuring that any emerging hotspots or fire risks are detected immediately. This is particularly important in facilities where continuous operation is required, such as power plants, data centers, and manufacturing facilities, where even a short delay in detecting a hazard can lead to catastrophic consequences.

Beyond preventive inspections, real-time monitoring also enhances emergency response efficiency: Thermal imaging cameras integrated into real-time monitoring systems can automatically alert safety personnel when temperature thresholds are exceeded. These alerts can be sent via centralized monitoring systems, ensuring that response is immediate. In addition, real-time thermal imaging allows for remote monitoring, enabling safety teams to oversee multiple locations from a central command center. This not only improves efficiency but also reduces the need for on-site personnel to work in high-risk environments.

The significance of real-time monitoring extends beyond fire prevention to emergency response. In the event of a fire, real-time thermal imaging provides firefighters with critical information about fire location, the spread of the fire, and the presence of trapped individuals.

About Raytron

As a global leading innovator in infrared thermal imaging, Raytron continues to develop thermal imaging solutions that drive advancements in fire prevention and emergency response. Raytron aspires to cooperate with more frontline fire and rescue organizations in the future to safeguard the lives and safety of communities. Guided by the vision of expanding infrared imaging as a standard in fire protection equipment and first responder gear, Raytron is empowering frontline rescuers with reliable thermal imaging tools and helping pave the way for more effective fire risk mitigation and safer emergency operations.