How Optical Gas Imaging (OGI) Cameras Stop Hazardous Gas Leaks Before They Become Disasters

As the world marks the International Day for the Preservation of the Ozone Layer, attention is turning to a new generation of greenhouse gases undermining atmospheric recovery. While the Montreal Protocol successfully phased out CFCs, emissions of CH₄ and sulfur SF₆—potent contributors to global warming—continue to rise. In this global effort, Raytron is providing the eyes to see these invisible threats, turning the abstract into the actionable with its advanced OGI solutions.

From Contact to Remote: Thermal Imaging is Revolutionizing Gas Leak Detection

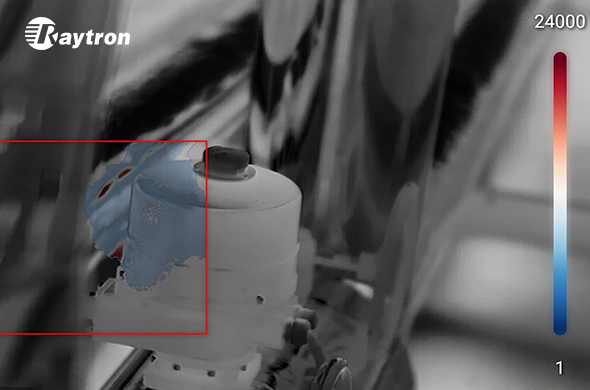

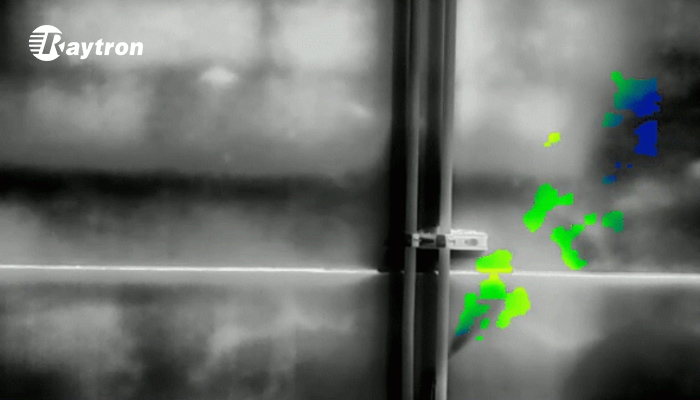

Traditional methods of gas leak detection require proximity to potential leak sources with point sensors, which is laborious, slow and hazardous. In contrast, OGI cameras use infrared technology to visualize gas leaks that are invisible to the naked eye. By detecting specific infrared wavelengths absorbed by industrial gases such as methane and volatile organic compounds (VOCs), infrared thermal cameras display real-time, smoke-like imagery of leaks. This enables surveys from safe distances, reduces inspection time, and enhances detection accuracy, even in challenging environments.

Why Raytron’s OGI Cameras Are Gaining Attention in Industrial and Environmental Monitoring?

Taking advantage of its pioneering thermal imaging technology, Raytron launched a series of high-sensitivity gas imaging cameras. Its flagship handheld OGI camera incorporates a 640×512 infrared detector with 15mK thermal sensitivity, allowing it to detect even minor methane leaks and other industrial gases with high clarity. Custom optical filters improve signal-to-noise ratio, while AI-driven gas cloud visualization algorithms support real-time alerts, provide real-time analytics on plume size and concentration, prioritizing repairs and streamlining reporting for environmental compliance. Beyond handheld thermal imagers, Raytron offers fixed-mount and UAV-based thermal solutions, covering diverse gas detection scenarios.

“Our goal at Raytron is to arm industries and regulators with the most precise and reliable infrared thermal imaging tools to tackle climate change at its source,” said Sharon, Director of Infrared Division at Raytron. “By making the invisible visible, we’re not just selling cameras; we’re providing a foundational technology for accountability and environmental stewardship in the decarbonization era.

How Does Optical Gas Imaging Help Protect the Ozone Layer?

A growing number of organizations, from industries to government, are adopting OGI cameras to reduce atmospheric pollution.

lPetrochemical Industry: Use OGI cameras to inspect kilometers of pipelines, valves, flanges, and tanks for methane and VOC leaks, reducing air pollution emissions.

lElectrical Facilities: Deploy SF₆ leak detection cameras to identify and repair leaks of this highly potent greenhouse gas in switchgear and transformers.

lEnvironmental Monitoring: Adopt OGI for emissions audits, enforcement and public reporting, supplying robust evidence for policy and accountability.

lWaste Management and Landfills: Monitor for methane leaks, a byproduct of decomposition with more than 80 times the warming power of CO₂, and facilitate capture-reuse systems.